Due to the high-risk nature of operations, safety measures in the oil and gas industry are essential. These measures protect workers, the environment, and assets while safeguarding companies' reputations and financial stability. Mitigating occupational hazards is crucial for preventing accidents, injuries, and fatalities and fostering a safe working environment.

Understanding Occupational Hazards in the Oil and Gas Industry

Occupational hazards in the oil and gas industry encompass a range of risks, including falls, chemical exposure, fires, explosions, and equipment failures. Each hazard presents unique dangers, such as respiratory issues from exposure to toxic gases, burns from fires, or injuries from machinery accidents. Proper risk assessment and hazard identification are essential for effectively anticipating and addressing these dangers.

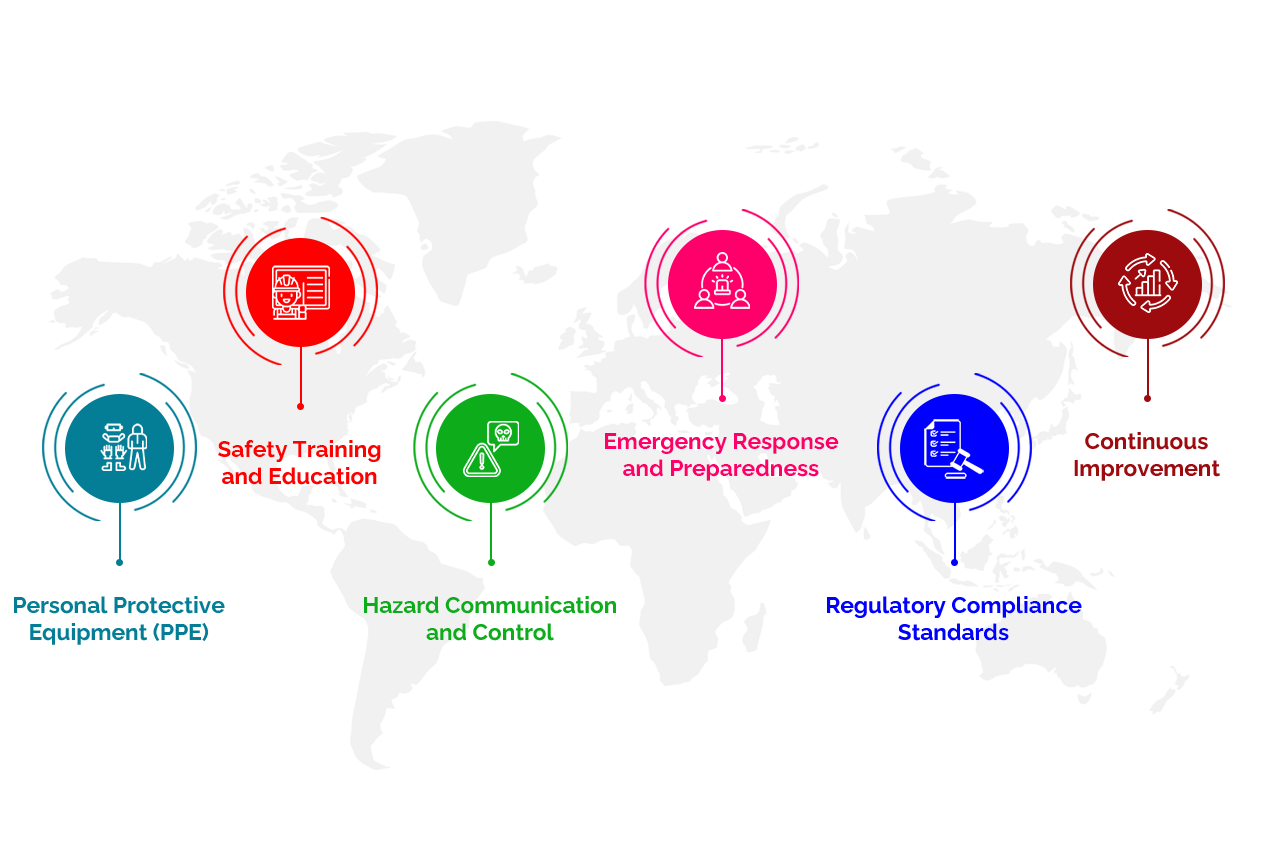

Essential Safety Measures in the Oil and Gas Industry

1. Personal Protective Equipment (PPE)

PPE protects workers from various hazards by providing a physical barrier. It includes helmets, gloves, goggles, and respiratory protection. Proper selection, use, and maintenance of PPE are vital to ensure its effectiveness in safeguarding workers.

2. Safety Training and Education

Comprehensive safety training programs equip workers with the knowledge and skills to identify hazards, respond to emergencies, and adhere to safety protocols. Training should cover topics such as hazard recognition, proper use of equipment, and emergency procedures and be conducted through interactive and engaging sessions.

3. Hazard Communication and Control

Effective communication about hazards ensures that workers know potential risks and understand how to mitigate them. Strategies for hazard control may include engineering controls, administrative controls, and personal protective measures. Implementing robust hazard communication programs facilitates the dissemination of crucial safety information throughout the organization.

4. Emergency Response and Preparedness

An emergency response plan outlines procedures for addressing various scenarios, including fires, spills, and medical emergencies. Regular drills and exercises help ensure workers are prepared to respond effectively in real-life situations. Creating a culture of preparedness encourages proactive measures and instant action during emergencies.

5. Regulatory Compliance Standards

Regulatory authorities establish guidelines and standards to maintain safety in the oil and gas industry. Compliance with these regulations is mandatory to prevent accidents and maintain operational integrity. Adhering to industry standards ensures best practices are followed, promoting a culture of safety and accountability.

6. Continuous Improvement

A strong safety culture is built on continuous improvement, prioritizing safety at all organizational levels. Fostering such a culture requires leadership commitment, employee involvement, and ongoing evaluation of safety processes. Embracing a continuous improvement mindset leads to enhanced safety practices and reduced incidents.

Why NeoEHS Risk Management Software?

Transform your approach to occupational hazard management effortlessly with NeoEHS risk management software. Build a culture of safety in your workplace with our comprehensive HSE solution, featuring customizable dashboards, user-friendly accessibility, live reporting, and insightful analytics. Seamlessly integrate our HSE software with your existing technology platform. Don't hesitate any longer – book a free demo now and unlock the full potential of our platform.

Final Thoughts

Prioritizing safety measures in the oil and gas industry is paramount for protecting workers, the environment, and company assets. Organizations can mitigate occupational hazards by implementing essential safety measures, adhering to regulations, and building a safety culture. Industry stakeholders must embrace safety as a core value and commit to continuous improvement to safeguard lives and promote sustainable operations.