Nowadays, most manufacturing industries face a rise in the number of incidents across their workplace. According to a survey, the industry experiences more than thousands of incidents yearly. If your industry isn't focusing on these facts, you neglect the opportunities to enhance workplace safety. These incidents not only impact your employees' lives but also minimize your overall productivity and efficiency.

Is your manufacturing industry equipped to handle incidents? Workplace safety must be every industry's priority; hence, it is essential to implement incident management software to prevent incidents and minimize potential hazards.

What Is Incident Management Software?

Incident management software is a comprehensive solution designed to manage and respond to incidents, emergencies, or disruptions and ensure compliance with regulatory standards. By streamlining the incident management process, you can identify potential risks before they turn critical and reduce future incidents.

In this blog article, let's discuss the evolution of incident management software in the manufacturing sector and explore its transformative impact.

Overview of Incident Management in the Manufacturing Sector

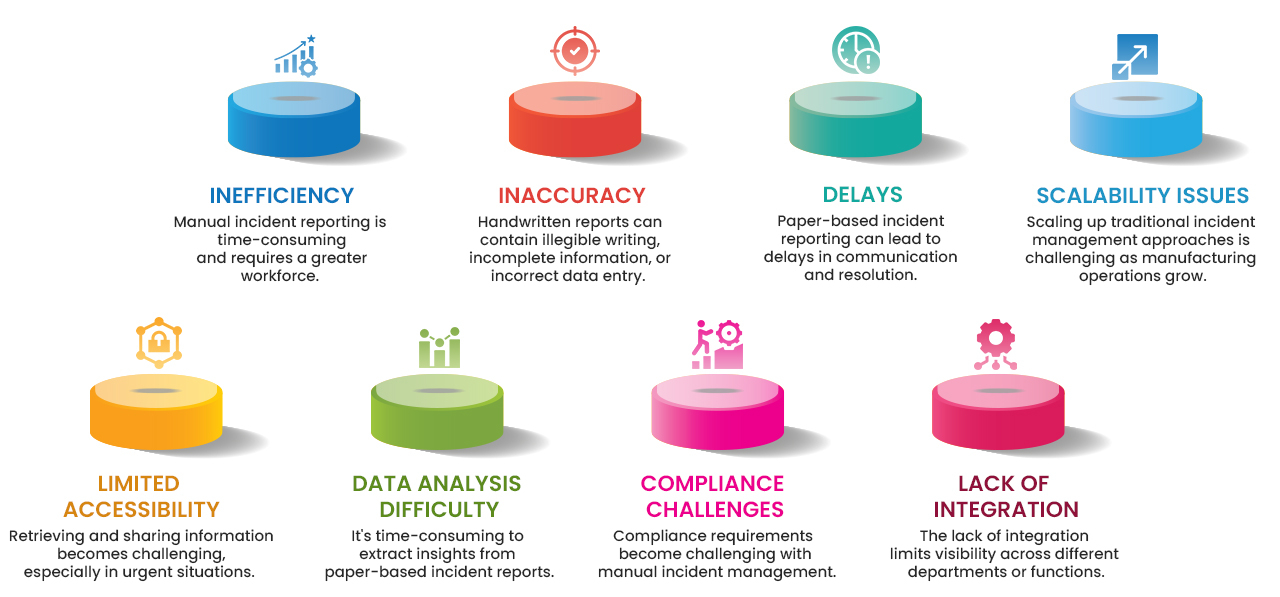

During the early stages of manufacturing, incident management heavily relied on manual procedures and paper-based documentation. Workers were tasked with completing incident reports manually, resulting in inefficiencies, delays, and inaccuracies. Retrieving historical data for analysis or compliance requirements was laborious and time-intensive.

Challenges of Traditional Incident Management Approaches

Transition to Digital Incident Management Solutions

As technology advanced, manufacturing industries began transitioning to digital incident management solutions. Many industries have started leveraging HSE software for instant incident reporting and tracking, streamlining processes, and improving data accuracy. These solutions have a significant impact on minimizing incidents before they occur.

Key Features and Functionalities of Incident Management Software

Customizable Solutions

Incident management software can be customized based on the organization's requirements.

Streamline Workflows

Automating incident management processes has revolutionized incident response, enabling predictive analytics and proactive risk mitigation.

Incident Reporting and Tracking

Advanced incident reporting provides comprehensive dashboards and customizable metrics, empowering decision-makers with actionable insights.

Easy Accessibility

The incident reporting software can be accessed anytime, anywhere, allowing frontline workers to report incidents directly from the field using any device.

Real-Time Notifications

When an incident occurs, this software sends instant notifications to employees, enabling them to perform quick and effective CAPA.

Integration with Other Systems

Integration with other enterprise systems, such as ERP, CRM and much more, enables seamless data flow and real-time collaboration across departments.

Benefits

- Improved incident response

- Advanced visibility and transparency in incident management processes

- Reduction in operational costs and productivity losses

- Compliance with regulatory requirements and standards

- Enhanced risk management

Future Trends and Advancements in Incident Management Software

The evolution of incident management software in the manufacturing sector shows no signs of slowing down. AI-powered predictive analytics will continue to enhance risk assessment and identify potential incidents before they occur. In addition to that, virtual reality (VR) simulations will enable workers to have immersive training experiences, enhancing safety awareness and preparedness. Likewise, the advancements in HSE software, including wearable devices, integration with IoT and machine learning technologies, and much more, can significantly reduce workplace incidents.

Final Thoughts

The transformation of incident management software in the manufacturing industry has evolved companies to identify, respond to, and mitigate risks. From manual processes and paper-based systems to AI-driven predictive analytics and cloud-based platforms, the evolution has been marked by innovation and progress. Leveraging these advancements empowers manufacturing organizations to prioritize safety, optimize operations, and achieve sustainable growth in an increasingly complex and competitive landscape.